Sometimes, a traditional technology becomes surprisingly powerful when used in a new way.

Gravel filtration is one such method—it may even transform the future of water supply systems.

In Japan’s water supply history, the main purification methods have been rapid sand filtration and slow sand filtration.

Both methods use sand as the primary filtration medium.

Gravel has also been used in the water industry, but more as a support layer for sand rather than as a filter medium itself.

Now, gravel itself is being used directly for filtration—and it’s a game changer.

To begin with the results: it provides astonishing turbidity removal.

Moreover, it reduces TOC (Total Organic Carbon) in the water and even removes general bacteria and E. coli.

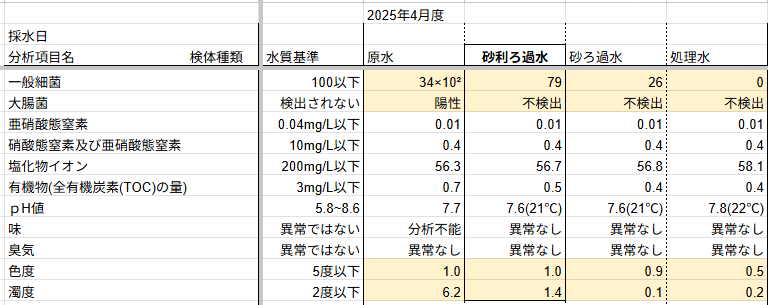

The following is a water quality analysis from one of the test sites.

In this case, river water is first treated with gravel filtration, followed by sand filtration, and finally sterilized with chlorine.

As shown in the table, even after the gravel filtration stage, turbidity, general bacteria, E. coli, and TOC levels have all decreased.

Water quality standards define whether water can be officially supplied as drinking water—and gravel filtration alone already meets these standards.

What’s more, neither the gravel nor sand filtration steps use any chemicals.

It’s simply water passing through gravel and sand.

That said, various design considerations are involved, and maintenance is typically required every two weeks. However, by incorporating some automation, the frequency of maintenance can be significantly reduced.

Compared to other water purification methods, gravel and sand filtration requires less mechanical equipment and fewer chemicals, making it dramatically more cost-effective over 20 to 50 years of operation.

We aim to spread this combination of gravel and sand filtration throughout Japan and the world, promoting a clean and affordable method of water purification.