— The Cutting Edge of Seawater Desalination: Turning the “Blue Ocean” into Drinkable Water —

Roughly 97.5% of the Earth’s water is seawater. Only about 2.5% is freshwater available for human use. Despite this, only 0.8% of the world’s total potable water supply comes from desalinated seawater. Why is that?

This is due to the historical and technical challenges of desalination, as well as its high costs. However, with growing water shortages driven by climate variability and advances in technology, expectations are rising for this “technology that turns the blue sea into drinkable water.” In this article, we explore the current frontier and future of desalination.

The Reality of Usable Water on Earth

The total volume of water on Earth is approximately 1.386 billion km³. Of that, freshwater accounts for only 35 million km³, or 2.5%. Furthermore, about 70% of this freshwater is trapped in glaciers or snow, making rivers, lakes, and groundwater the only sources directly accessible to humans.

Under such constraints, humanity has long relied on rivers, lakes, and groundwater for its water supply.

However, for decades, desalination has been viewed as a promising solution for securing stable water resources. Although early technologies faced issues with cost and efficiency, the widespread adoption of methods like reverse osmosis (RO) membranes has become a practical reality thanks to recent innovations.

The Volume and Usage Gap Between Freshwater and Seawater: “Plenty, but Inaccessible”

There is a fundamental issue with seawater: despite its abundance, it’s unusable in its natural state. With a salinity of around 3.5%, it cannot be used for drinking, agriculture, or most industrial applications without treatment.

As of 2023, over 100 million m³ of seawater is desalinated each day globally. However, this accounts for just 0.8% of the world’s total annual water consumption. Clearly, desalination has yet to become a mainstream source of potable water.

Leading Regions and Motivations for Desalination: Where Water Is Scarce and Fuel Is Cheap

Desalination is most prevalent in regions that lack water resources but have abundant and inexpensive energy supplies.

- Gulf countries such as Saudi Arabia, UAE, and Kuwait: These nations have extremely limited groundwater, hence the phrase “water from the neck down.” With cheap access to fossil fuels, they operate some of the world’s largest desalination facilities, often relying almost entirely on desalinated water.

- Israel: With much of its territory classified as arid, Israel supplies 60% of its drinking water through seawater desalination. Backed by high technical capability and a national strategy, Israel operates numerous efficient desalination plants.

For these nations, desalination has become a critical infrastructure for national survival and economic sustainability.

Japan’s Case: Fukuoka and Okinawa Leading the Way

Japan generally enjoys abundant rainfall, but some regions suffer from chronic water shortages. In areas reliant on rain, desalination plants serve as emergency buffers during droughts.

- Fukuoka (Uminonakamichi): Home to one of Japan’s largest desalination plants, it supplies 50,000 m³/day, playing a key role in meeting demand during dry periods.

- Okinawa (Chatan Yadomari): Utilizes a mixed water source combining groundwater and desalinated seawater. This system aims to effectively use limited freshwater and ensure stable supply, with a daily output of 40,000 m³.

These cases show that even in a relatively water-rich country like Japan, seawater desalination can significantly contribute to regional water stability.

Technical Overview: Reverse Osmosis (RO) Membranes at the Core

The main technology behind seawater desalination is the reverse osmosis (RO) membrane. These membranes have ultra-fine pores of about 0.0001 μm, allowing water molecules to pass through while blocking salts, viruses, and heavy metals almost completely.

However, this process requires high pressure to push seawater through the membranes. Without proper pre-treatment, membrane clogging occurs quickly. Therefore, pre-filtration and chemical treatments are necessary before RO processing.

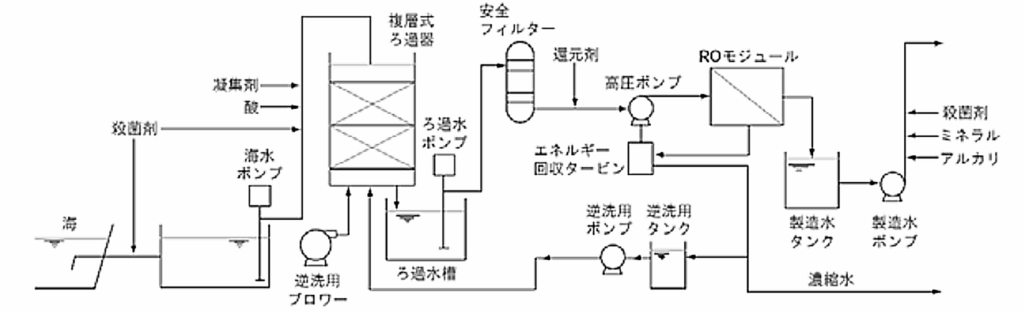

The RO desalination process typically follows these steps:

- Pre-treatment: To protect the RO membrane and prevent clogging, impurities such as sand, silt, and microbes are removed through coagulation, sedimentation, and membrane filtration using UF (ultrafiltration) or MF (microfiltration).

- High-pressure pumping: The pre-treated seawater is pressurized using high-pressure pumps. At around 6–7 MPa, water molecules pass through the membrane against the osmotic pressure.

- Separation into freshwater and brine: Water that passes through becomes freshwater for drinking and other uses. The remaining 5–8% high-salinity concentrate is discharged as brine.

- Freshwater: Typically, 40–45% of the input water is recovered as freshwater, with the rest being discharged as brine.

*For comparison, water mains pressure that can cause water to spurt out when pipes burst is around 0.3–0.5 MPa—about one-tenth of the pressure used in RO systems.

Pre-treatment: The Lifeline of RO Membranes

Pre-treatment is essential for maximizing membrane performance and extending its life. It’s often said, “RO membranes can last three times longer with proper pre-treatment.”

Without sufficient pre-treatment, impurities accumulate on the membrane surface, causing clogging and performance loss—a problem known as fouling. This leads to more frequent cleaning and earlier membrane replacement, greatly increasing operational costs.

For example, removing particles smaller than 0.1 μm and keeping turbidity (NTU) below 1 can help maintain membrane performance and extend its service life.

Typical methods include UF or MF membranes, or sand filtration combined with coagulant agents for removing suspended solids.

Cost Structure and Energy Recovery: The Key Is Electricity

The biggest challenge in desalination is cost—particularly energy costs. Pressurizing seawater through RO membranes consumes large amounts of electricity.

- Energy consumption per cubic meter: ~2.5–3.5 kWh (RO method). For example, the Fukuoka plant (50,000 m³/day) would require ~150,000 kWh daily—roughly the daily electricity needs of a city of 40,000 people.

To reduce this energy burden, Energy Recovery Devices (ERDs) are used. These systems recover pressure energy from concentrated brine and reuse it, reducing electricity consumption by around 40%. Since electricity accounts for 35–50% of RO plant operational costs, this is a major cost-saving innovation.

Solar + RO initiatives: To lower power usage further, solar-powered RO systems are being tested as eco-friendly desalination alternatives.

Environmental Concerns and Solutions: Smart Brine Discharge

Brine is the concentrated seawater left after desalination. It has about twice the salinity of seawater and may contain chemicals from treatment processes. Direct discharge into oceans can harm marine ecosystems.

Key mitigation strategies include:

- Offshore dispersion using density gradients: Brine is discharged offshore where it can mix thoroughly with surrounding seawater, minimizing localized salinity spikes.

Hybrid Models with Wastewater Reuse: Closing the Urban Water Loop

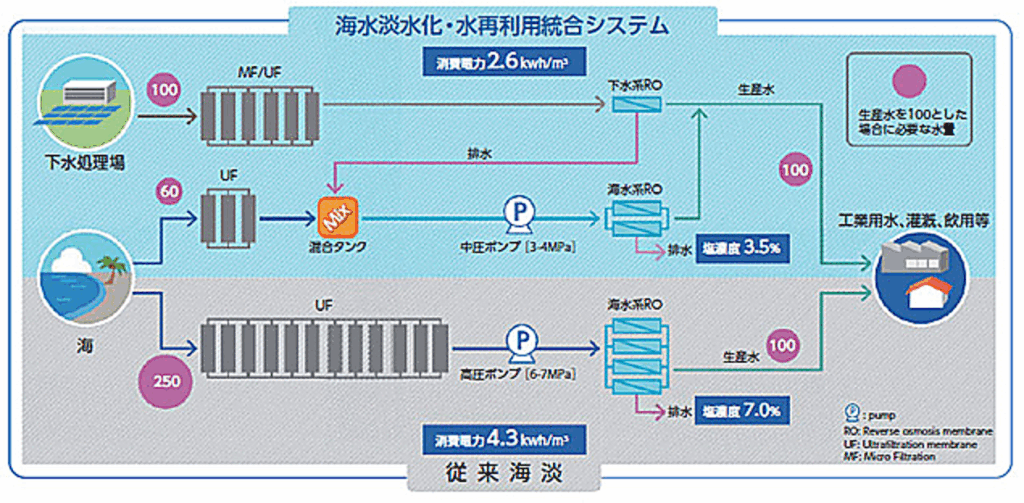

Sustainable water management increasingly relies on combining seawater desalination with wastewater reuse in hybrid systems.

- Singapore’s “NEWater”: A pioneering example of advanced wastewater recycling, providing drinking water through a combination of reclamation and desalination. This reduces reliance on external sources.

- Cape Town, South Africa: Faced with critical water shortages, the city explored combining wastewater treatment and seawater desalination as a secure water source.

This approach avoids dependence on a single solution, instead building a robust and sustainable water supply through diverse technologies and sources.

Future Outlook: Desalination Will Grow in Importance Through Innovation and Decarbonization

Desalination technology continues to evolve, with the following developments on the horizon:

- Energy use below 2 kWh/m³: Ongoing R&D aims to reduce energy demand for more cost-efficient desalination.

- New materials like graphene membranes: These next-gen membranes promise high efficiency at lower pressure.

- Modular and decentralized systems: Small-scale units can provide localized water supply in diverse regions.

- Rare metal recovery from brine: Extracting lithium and other valuable elements could lower environmental impact and generate economic returns.

Conclusion

“The ocean is infinite, electricity is not.” In regions with limited water resources, desalination is becoming increasingly important. Reducing energy use and environmental impact will be key going forward.

With ongoing innovations and the global push for decarbonization, seawater desalination is poised to become a more sustainable and vital water supply source.

In the next article, we’ll explore the use of compact RO systems for household or local applications.