When turning mountain stream water into a public water supply, one challenge that often troubles water treatment engineers is the presence of colored substances known as humic substances.

These substances, believed to dissolve into the water as it passes through fallen leaves in the forest, give the water a light brown hue and can result in color intensity levels exceeding the regulatory limit of 5 degrees for drinking water.

A few years ago, I worked on a renovation project at a small water treatment plant in Chiba Prefecture and struggled with the issue of color caused by humic substances. In this article, I aim to explain this issue in a simple manner, including the discoveries made, the final solution implemented, and even some surprising facts.

What Are Humic Substances (Humic Acid)?

According to Wikipedia, humic substances are introduced as follows:

Humic acid is an acidic, amorphous high-molecular-weight organic substance formed as a final product of the decomposition of plants by microorganisms, and is one of the components of humic substances. In a narrower sense, it refers to the reddish-brown to dark brown fraction of organic matter that is soluble in alkali and precipitates in acid, found in humus and soil. It is not classified as sugar, carbohydrate, protein, or lipid. It is also known as fulvic acid.

Many water treatment engineers have long struggled and battled with these humic substances and humic acids.

Needs from the Local Community

The residents of the target area have long suffered from discolored local tap water.

- White shirts turn light brown after washing.

- Bathwater is always light brown and sometimes cloudy.

- They envy the clean water whenever they travel.

Among many requests, addressing water discoloration was identified as a top-priority issue.

At the time of our investigation, the raw water’s color intensity varied with the weather, but it was generally about 8 degrees on sunny days, and reached nearly 40 degrees in extreme cases.

Treatment Methods Considered

When considering countermeasures for color removal, water treatment experts typically consider the following two options:

- Color removal using activated carbon filtration

- Oxidative decomposition of colored substances using ozone

Here is a brief explanation of each treatment method:

Color Removal Experiments

Experiment Using Activated Carbon

We conducted color removal experiments using coconut shell activated carbon, which is commonly used in the water treatment industry.

Initially, the color was successfully removed right after water started flowing through, but it quickly reached a state known as “breakthrough”1, where colored substances started leaking through. We then switched to coal-based activated carbon for further testing. Although performance slightly improved, the volume of water treated before breakthrough still suggested that several replacements per year would be necessary at this site.

In a typical water treatment plant, such maintenance costs might be manageable. However, in a depopulated rural area where a handful of households bear the operating costs, color removal via activated carbon was deemed unrealistic. As a result, this method was ruled out.

Experiment Using Ozone Oxidation

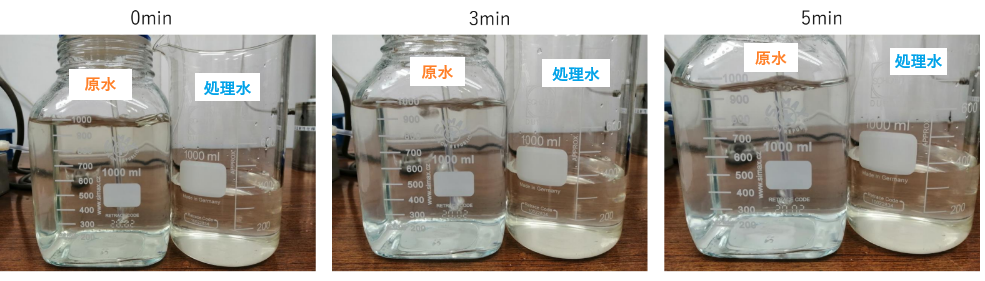

The ozone oxidation experiment began with aeration tests in a beaker.

The results showed that 80% of the color was removed with 2 minutes of ozone aeration, and an additional 10% (for a cumulative 90%) was removed with one more minute. However, the remaining 10% did not significantly change even after more than 10 minutes of aeration, suggesting a different coloring component. Nevertheless, removing 90% of the color brings the color intensity down from 8 degrees to 0.8 degrees—well within the regulatory limit of 5 degrees.

After the beaker tests, we conducted further experiments using an aspirator to simulate on-site aeration. The results were similar in both duration and effectiveness.

To eliminate concerns about nitrogen oxide generation from air-based ozone and to improve ozone dissolution efficiency in water, we introduced both an ozone generator and an oxygen concentrator. The final ozone oxidation system used an oxygen-fed ozone generator with a gas-liquid mixing pump.

Other Color Removal Methods

As part of the renovation of the small-scale water purification plant, the client strongly requested that membrane filtration be used as a treatment method.

We struggled with membrane selection, but after deciding on an MF (microfiltration) membrane, we conducted tests to evaluate its effectiveness. The results showed that color intensity was reduced to below 1.5, and sometimes even below 1.

Based on these findings, we ultimately adopted a dual-treatment approach combining ozone oxidation + MF membrane filtration as the color removal strategy for this site.

Concerns About MF Membrane Clogging

Just when we thought the issue was resolved, the membrane manufacturer warned us that although MF membranes are effective for removing color, humic substances could cause early clogging.

However, they were unable to provide concrete measures for preventing or restoring clogs, and no effective comments were offered regarding countermeasures.

Since ozone oxidation can break down such substances, we decided to move forward with a “we’ll manage somehow” mindset and concluded the countermeasure study.

Color Removal Using Biological Treatment

Before the full system was installed, we conducted a three-month test using biologically active media such as gravel and sand filters. Although it was summer and microbial activity should have been high, the color was barely reduced. In fact, in some cases, the color intensity increased. We concluded that biological treatment was not a viable solution for color removal.

Design Considerations

When proceeding with the design, we incorporated the following considerations:

- Installed a biological sand filter downstream of the ozone system to promote biodegradation of ozone byproducts and reduce clogging load on the MF membrane.

- To prevent residual ozone from killing the microbes in the biological sand filter, we added an intermediate layer of activated carbon to decompose ozone into oxygen before it reached the biological stage.

- The ozone system was designed to operate based on raw water quality, with ON/OFF control implemented accordingly.

These design decisions would later stir some debate during operational stages—more on that later!

After Commissioning the Facility

Despite a very tight construction schedule, we managed to complete the facility and began trial operations.

After testing each component, the entire plant began stable operation. At that point, color removal was being conducted under the following conditions:

• Ozone system: 100% output, continuous operation

• MF membrane filtration: Operated at the designated flow rate

Formation of Bromate by Ozone Oxidation

Initially, color removal went smoothly, and the treated water consistently achieved a color intensity of around 0.1–0.2. However, during a standard 51-parameter water quality analysis, a serious issue was discovered.

Bromate formation due to ozone treatment.

Even though color was removed, bromate levels exceeded drinking water standards—this was a major issue.

Responding to Bromate

Years ago, during a JICA water project in Sudan, we encountered a nationwide problem when bromate levels exceeded limits in Coca-Cola’s ozonated bottled water production, which used underground water. I never expected to face a similar problem at this site.

Though the possibility of bromate crossed my mind during the design phase, I assumed it wouldn’t be a concern because bromide ions are typically present in groundwater—not surface water. That assumption, combined with the tight schedule, led us to skip analysis for bromate risk entirely.

Once bromate was detected in the standard 51-parameter water test, we had no choice but to develop countermeasures.

However, introducing new equipment was not feasible due to the limited construction schedule, ongoing operations, and cost considerations.

We therefore focused on operational strategies—namely, reducing ozone output to the lowest possible level that would still ensure color removal without forming bromate.

By trial and error, we miraculously discovered the optimal range:

- Increasing ozone output beyond this point resulted in bromate levels exceeding standards, even though color was reduced.

- Decreasing output further stopped bromate formation but failed to sufficiently reduce color.

This “sweet spot” achieved color removal without forming bromate.

We were very concerned whether this would truly work, but fortunately, the setting proved effective.

Subsequent testing confirmed that this ozone setting was effective regardless of weather conditions, such as rain or sunshine, and bromate has not been detected in any of the facility’s regular 51-parameter water quality tests since then.

Considerations During Design Phase

During the bromate setting validation, we also analyzed the cause—bromide ions—and made a shocking discovery:

No detectable bromide ions were found in the raw water used for ozone treatment. Yet, bromate levels exceeded the regulatory limit after high-output ozone treatment on the same day.

This implies that even if we had conducted pre-design testing, we likely would not have detected bromide ions. However, testing the treated water for bromate during ozone experiments should have been done—this was a key lesson learned.

For reference, here are the water quality standards related to bromate and bromide ions:

Bromate: Must be 0.01 mg/L or lower according to drinking water standards

Bromide ion: No official standard; detection limit is 0.1 mg/L (reporting threshold for operational purposes)

Biological Filtration Not Functioning

Now to another issue, separate from bromate.

We had installed a biological sand filter downstream of the ozone system to promote further decomposition of ozone byproducts. However, even after one month of operation, there were no signs of microbial activity. We were puzzled.

We later discovered the reason: ozone was so active that it killed all microorganisms entering the biological filter, rendering it biologically inactive.

During a test period where the ozone system was shut down for over a month, microbes naturally flowed into the biological filter. We observed signs of microbial activity and confirmed through water quality analysis that the filter had become biologically active again. This was a great relief.

Even under low-output ozone conditions, the system continued to produce good results.

Rising Electricity Costs

Besides ozone oxidation and MF membrane filtration, the small-scale plant was equipped with UV disinfection and an automatic chlorine dosing system. As a result, electricity costs surged, prompting us to re-evaluate optimal operational conditions.

We especially focused on determining what level of color intensity would justify operating the ozone system, to minimize the burden on the MF membrane and reduce power consumption.

Based on this analysis, we proposed an operational plan that specified the threshold color level for activating ozone oxidation. The client accepted this plan.

Below is a photo of the actual treatment plant after renovation:

Operation of MF Membranes

In addition to color, we were also concerned from the beginning about how long MF membranes could be used before needing replacement. This was a key issue to resolve.

“The color is gone, the water quality is good, but if we have to replace MF membranes every month, it would be financially unsustainable.”

To extend the operational life of MF membranes—especially under increased load caused by using them without ozone when color levels were low—we needed to establish an effective chemical cleaning method. While the manufacturer provided general instructions, we conducted extensive tests under various conditions to find the best approach.

As a result, we developed an optimal cleaning and operation method. The same MF membrane used since trial operations is still in use today, even three years later.

Final Reflections on the Color Removal Strategy

In conclusion, based on the results of our color removal efforts, I’d like to share some speculative insights about the underlying principles. These are largely my own hypotheses and not necessarily scientifically proven:

- As described in the Wikipedia excerpt, humic substances are “acidic, amorphous high molecular weight organic compounds,” likely with large structural sizes.

- Because of their size, they cannot easily fit into the micropores of activated carbon, leading to early breakthrough.

- On the other hand, high molecular compounds are susceptible to ozone oxidation, and once broken down, they lose their coloring properties—explaining the observed decolorization.

- Similar to artificial high-molecular substances like diet sweeteners, humic substances may not be readily biodegradable, which is why biological treatment is ineffective at color removal.

- Since membrane filtration is a physical process, it is well-suited for removing large molecules like humic substances, making color removal via membranes quite natural.

- The success of chemical cleaning in removing humic-related buildup suggests that the approach targeted characteristics of these organic macromolecules. Using both alkaline and acid cleaning solutions improved recovery, likely due to dissolving other fouling agents such as metallic ions.

- The remaining 10% of color that ozone couldn’t remove may be caused by such metallic ions. Although we tested for iron at the time, none was detected—so another metal might be responsible.

- The molecular size of humic substances might vary by region. If some areas contain smaller molecular variants, coal-based activated carbon might work better in those cases.

This concludes the summary of our humic substance countermeasures in water treatment.

On a broader note, not all rivers are discolored, and I’ve rarely heard of humic-colored deep well water (though I may just be unaware). I suspect that somewhere in the natural environment, these substances are being decomposed by natural forces. If we could uncover that mechanism, it could be a groundbreaking discovery for the water industry.